Ferro Boron, an essential alloy in metallurgical and industrial applications, plays a vital role in the production of high-performance materials due to its unique chemical properties and characteristics.

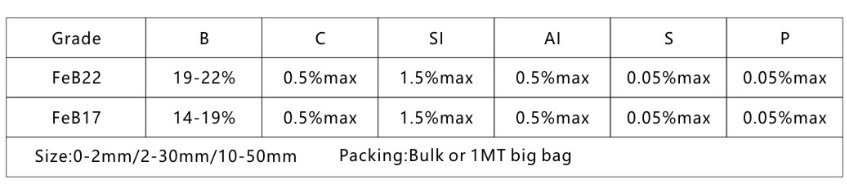

Specification of Ferro Boron

Key Properties of Ferro Boron

- High Strength and Corrosion Resistance: The boron content enhances the hardness and strength of the material, providing excellent corrosion resistance.

- High Melting Point and Thermal Stability: With a melting point exceeding 2000°C, Ferro Boron is ideal for high-temperature industrial processes.

- Material Performance Enhancement: Boron improves the hardness, toughness, and fatigue resistance of steel, making it an essential additive for high-performance alloys.

Major Applications of Ferro Boron

Ferro Boron has diverse applications across multiple industries. Below are its primary uses:

(1) Steel Industry

- Alloying Additive: Adding Ferro Boron to steel improves its mechanical properties and oxidation resistance, particularly in high-quality alloy steel and spring steel production.

- Welding Materials: Used in electrodes and welding fluxes to enhance wear resistance and strength.

(2) Rare Earth Permanent Magnets

- Ferro Boron is a key raw material in the production of NdFeB (neodymium-iron-boron) permanent magnets, widely used in electric motors, wind turbines, and electronic devices.

(3) Specialty Alloys

- It is utilized in manufacturing high-strength aluminum alloys, heat-resistant alloys, and specialized alloys for nuclear applications.

Global Market Analysis for Ferro Boron

(1) Increasing Demand

- The rising need for high-performance steel and permanent magnets is driving steady growth in the demand for Ferro Boron. Industries like electric vehicles, renewable energy, and advanced manufacturing are key contributors to this trend.

(2) Production and Consumption

- Leading Producers: China is the largest producer of Ferro Boron, followed by Russia and India.

- Major Consumers: Asia (notably China and India), Europe, and North America are the main consumption regions.

(3) Challenges and Opportunities

- Limited boron mineral resources and stricter environmental regulations may impact production.

- With the growing emphasis on sustainable development and advanced materials, Ferro Boron is poised for innovative applications.

Future Development Trends

- Renewable Energy Technologies: Increasing demand for NdFeB magnets in EV motors and energy storage systems will drive Ferro Boron market growth.

- Green Metallurgical Techniques: Eco-friendly production processes will reduce the carbon footprint of Ferro Boron manufacturing.

- Advanced Material Research: As industries like aerospace and defense seek high-performance materials, Ferro Boron will become a critical additive for specialized alloys.

Contact Us Today!

We welcome inquiries in English, Español (Spanish), Русский язык (Russian), Français (French), and العربية (Arabic).

Our professional team will reply to you within one business day. Please feel FREE to contact us!

Your privacy is important to us,we are committed to marking sure your privacy is

confidential.