What is Ferrosilicon?

Ferrosilicon is an alloy primarily composed of iron (Fe) and silicon (Si). The silicon content in ferrosilicon typically ranges from 15% to 90%, and it is categorized into low-silicon, medium-silicon, and high-silicon varieties based on the silicon content. Ferrosilicon plays a critical role in steelmaking and casting due to its excellent deoxidizing and alloying properties.

Types of Ferrosilicon

Low-Silicon Ferrosilicon: With silicon content generally between 15% and 30%, this type is primarily used as a deoxidizer in steelmaking.

Medium-Silicon Ferrosilicon: Containing silicon between 30% and 50%, it is used in the production of medium to high silicon steel to enhance the strength and hardness of the steel.

High-Silicon Ferrosilicon: With silicon content over 50%, this type is mainly used in electromagnetic materials and high-performance steel production.

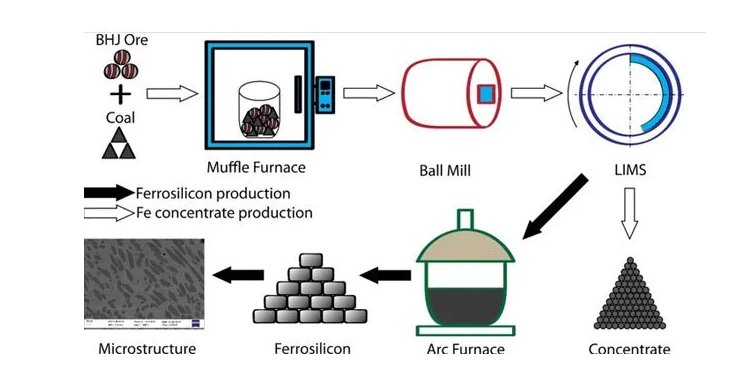

Production Process of Ferrosilicon

Ferrosilicon is typically produced through electric arc furnace smelting. In this process, iron ore and quartz are melted at high temperatures, undergoing chemical reactions to form the ferrosilicon alloy. The production process requires strict control of temperature and reaction time to ensure the quality of the ferrosilicon.

Applications of Ferrosilicon

- Steelmaking: Ferrosilicon is an essential deoxidizer in steel production, effectively removing oxygen from the molten steel to improve its properties.

- Casting: In casting, ferrosilicon is used to adjust the chemical composition of cast iron, enhancing the mechanical properties of castings.

- Electromagnetic Materials: High-silicon ferrosilicon is crucial in electromagnetic materials, widely used in manufacturing core components for motors and transformers.

- Alloying: As an alloying element, ferrosilicon enhances the hardness, toughness, and wear resistance of steel.

Factors to Consider When Choosing a Ferrosilicon Supplier

- Product Quality: Choose suppliers that offer high purity ferrosilicon to ensure stable product performance.

- Supply Capability: Evaluate the supplier's production capacity and delivery timelines to meet production requirements.

- Price Competitiveness: Compare prices from different suppliers to select products with good value for money.

- After-Sales Service: Opt for suppliers who provide excellent after-sales support to address any issues promptly.

Ferrosilicon, as an important alloy material, has extensive applications in steelmaking, electromagnetic materials, and casting. Choosing the right ferrosilicon supplier can enhance product quality and production efficiency, driving the continuous growth of your business.